Lab & Facilities

Laboratories

The laboratories/workshops are fully equipped with complete set of latest equipments and tools, which caters to the need of the undergraduate and post graduate students and has experienced technical staff from industrial background. The various labs and workshops encompass the vital aspects of Mechanical Engineering – Hydraulics, Machine Tools, Heat Engines etc. The major Laboratories are:1. Fluid Mechanics & Hydraulic Machines Lab

This Lab is intended to make the students aware of the all the aspects which comes under the fluid flow. The experiments include flow measurement, practical applications of the basic principles of fluid mechanics and the study of major tools used. The hydraulics lab comprises of the performance tests of pumps and load tests on turbine test rigs.

This Lab is intended to make the students aware of the all the aspects which comes under the fluid flow. The experiments include flow measurement, practical applications of the basic principles of fluid mechanics and the study of major tools used. The hydraulics lab comprises of the performance tests of pumps and load tests on turbine test rigs.

The Major equipments include:

- Flow Apparatus

- Venturimeter & Orificemeter

- Orifice & Mouth piece

- Pitot Tube

- Reynold’s Apparatus

- Notches (V & Rectangular type)

- Metacentric Height Apparatus

- Bernouli’s Theorem Apparatus

- Losses Determination Apparatus

- Test Rigs of Francis Turbine

- Kaplan Turbine

- Pelton Turbine

- Centrifugal Pump

- Reciprocating Pump

- Jet Pump

- Gear Pump

- Submersible Pump

- Hydraulic Ram

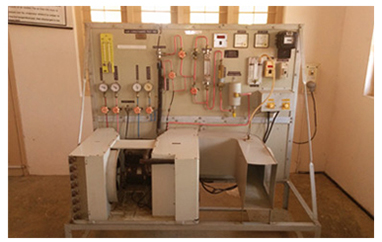

2. Heat Transfer Lab

This lab teaches the use of instrumentation and apparatus that are unique and/or special to the field of heat transfer. It demonstrates the fundamental aspects of heat transfer and employ’s experimental principles and thought processes to solve engineering problems.

This lab teaches the use of instrumentation and apparatus that are unique and/or special to the field of heat transfer. It demonstrates the fundamental aspects of heat transfer and employ’s experimental principles and thought processes to solve engineering problems.

The Major equipments include:

- Air Condition Test Rig

- Refrigeration Test Rig

- Emmisivity Measurement Unit

- Heat Transfer Through:

- Lagged Pipe Unit

- Composite Wall Unit

- Forced Convection Unit

- Natural Convection Unit

- Shell & Tube Heat Exchanger Unit

- Parallel Flow and Counter Flow Heat Exchanger Unit

- Thermal Conductivity of Metal Rod Unit

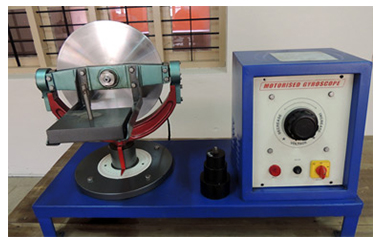

3. Mechanical Engineering Laboratory

The objective of mechanical engineering lab is to impart practical knowledge on the working of some basic instruments that are worked based on basic principles of engineering. This lab gives thorough idea about some principles that they already studied in previous years. Students become aware about the practical applications of Mechanical Engineering branch in our day to day life.

The objective of mechanical engineering lab is to impart practical knowledge on the working of some basic instruments that are worked based on basic principles of engineering. This lab gives thorough idea about some principles that they already studied in previous years. Students become aware about the practical applications of Mechanical Engineering branch in our day to day life.

The Major equipments include:

- Universal Governor

- Motorized Gyroscope

- Monocular Metallurgical Microscope

- Fluidized bed Apparatus Bearing Testing Machine

- Vibration Testing for Free & Forced Apparatus

- Sand Testing Apparatus

- Whirling of Shaft Demonstrator

- Dynamic Balancing Setup

- Air Compressor Single Stage Test Rig

- Multi Stage Test Rig

- Blower Test Rig

4. Machine tool Laboratory

The objective of Machine Tool Lab is to train students with different operations that can be carried out on lathe and milling machine .The students are well trained to prepare the models on lathe and milling machine. They also gain knowledge about different measuring devices like sine bar , vernier caliper etc.

The objective of Machine Tool Lab is to train students with different operations that can be carried out on lathe and milling machine .The students are well trained to prepare the models on lathe and milling machine. They also gain knowledge about different measuring devices like sine bar , vernier caliper etc.

The Major equipments include:

- All Geared Lathe

- Cone Pulley Lathe

- Universal Milling Machine

- Bench Drilling Machine

- Planning Machine

- Power Hacksaw

- Bench Grinder

5. Advanced Machine tool Laboratory

This lab emphasizes the use of different types of machines used in production field and make the students apt for the industry. To study the principle of operation, work holding and different operations of reciprocating machines like slotter and shaper. This lab acknowledges the scope of Computers in production technology and different expert systems used in manufacturing.

This lab emphasizes the use of different types of machines used in production field and make the students apt for the industry. To study the principle of operation, work holding and different operations of reciprocating machines like slotter and shaper. This lab acknowledges the scope of Computers in production technology and different expert systems used in manufacturing.

The Major equipments include:

- Slotting Machine

- Shaping Machine

- Universal Tool & Cutter Grinder

- Radial Drilling Machine

- Capston Lathe with Turret Head

6. Heat Engines Laboratory

This lab makes the student understand about the design concepts and principles of various engine components. It also imparts basic knowledge to students with respect to transmission system of automobiles and will enable the student to understand the latest developments in the field. This lab promotes the ability to select the appropriate strategy and equipment needed to perform a repair task. The heat engines lab comprises of the performance tests on various engines.

This lab makes the student understand about the design concepts and principles of various engine components. It also imparts basic knowledge to students with respect to transmission system of automobiles and will enable the student to understand the latest developments in the field. This lab promotes the ability to select the appropriate strategy and equipment needed to perform a repair task. The heat engines lab comprises of the performance tests on various engines.

The Major equipments include:

- Petrol Engine Test Rig

- Diesel Engine Test Rig

- Flash and Fire Point Apparatus

- Say Bolt Viscometer Apparatus

- Junker’s Gas Calorimeter Apparatus

- Cut Section Models & Working Models

7. Metrology & Mechanical Measurements Laboratory

This lab enables students to be familiar with the concepts of measurement. Students are trained to handle different measurement instruments like profilometer, strain gauges etc. The importance of dimensions in the industry and a close study of accuracy during manufacturing and machining various mechanical components.

This lab enables students to be familiar with the concepts of measurement. Students are trained to handle different measurement instruments like profilometer, strain gauges etc. The importance of dimensions in the industry and a close study of accuracy during manufacturing and machining various mechanical components.

The Major equipments include:

- Profile Projector

- Tool Makers Microscope

- Roughness Measuring Instruments

- Pressure Measuring & Calibrating System

- Vibration Measuring System

- Force Measuring System

- Non Contact Temperature Measuring Instrument

- Digital Stroboscope

- Dual Channel Strain Gauge Indicator

- Apparatus for Calibration of Rota Meter

- Water Meter

Mechanical Measurements Laboratory under Department of Mechanical Engineering is equipped Manual Coordinate Measuring Machine (Model: Crysta Plus M443; Make: Mitutoyo, Japan) procured under FIST project funded by Department of Science and Technology, New Delhi. The system is used to take and verify the geometrical accuracy of any part of interest with tolerance in micrometres. The equipment is set up with force modules for accurate operation of the machine without any distortion of the machine tools. Using the highly sensitive Renishaw make probing system with the interfacing software (MCOSMOS), the equipment can very well be used to evaluate and assess wide range of geometric features with ease. Different set of probes, that have ruby ball tip and tungsten carbide / stainless steel shanks, are available with the machine tool. Further, the provision for angular indexing of the probes enables measuring of intricate features that can be geometrically assessed by conventional means. Being a system that is widely used in industry, especially in the field of manufacturing, the system can be used in conjunction with research pertaining to conventional as well as additive manufacturing. Further, the application of equipment can be extended to its use in quality control of critical components that are manufactured as part of machine or system building.

Mechanical Measurements Laboratory under Department of Mechanical Engineering is equipped Manual Coordinate Measuring Machine (Model: Crysta Plus M443; Make: Mitutoyo, Japan) procured under FIST project funded by Department of Science and Technology, New Delhi. The system is used to take and verify the geometrical accuracy of any part of interest with tolerance in micrometres. The equipment is set up with force modules for accurate operation of the machine without any distortion of the machine tools. Using the highly sensitive Renishaw make probing system with the interfacing software (MCOSMOS), the equipment can very well be used to evaluate and assess wide range of geometric features with ease. Different set of probes, that have ruby ball tip and tungsten carbide / stainless steel shanks, are available with the machine tool. Further, the provision for angular indexing of the probes enables measuring of intricate features that can be geometrically assessed by conventional means. Being a system that is widely used in industry, especially in the field of manufacturing, the system can be used in conjunction with research pertaining to conventional as well as additive manufacturing. Further, the application of equipment can be extended to its use in quality control of critical components that are manufactured as part of machine or system building.

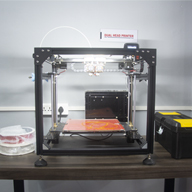

8. Additive Manufacturing LAB

Additive Manufacturing Zone, which is commonly known as FABLAB all over the world.3D printing, which is one of the most trending technique for product development in various domains like biomedical, aerospace etc., is a process of making three dimensional solid objects by laying down successive layers of material utilizing the data from a digital file.Additive Manufacturing Zone at Amal Jyothi College of Engineering, is a state of the art facility where anyone can work on an idea and build a prototype using the concept of 3D printing, which would help them to figure out a potential market for their product. The general purpose of this LAB is to empower people to make what they cannot buy in shops.The facility has potential for developing prototypes, fabrication of biomedical structures like hearing aids, prosthetics for amputees and disabled, toys and decorative products, demonstrative models for educational institutions etc. to name a few.

Additive Manufacturing Zone, which is commonly known as FABLAB all over the world.3D printing, which is one of the most trending technique for product development in various domains like biomedical, aerospace etc., is a process of making three dimensional solid objects by laying down successive layers of material utilizing the data from a digital file.Additive Manufacturing Zone at Amal Jyothi College of Engineering, is a state of the art facility where anyone can work on an idea and build a prototype using the concept of 3D printing, which would help them to figure out a potential market for their product. The general purpose of this LAB is to empower people to make what they cannot buy in shops.The facility has potential for developing prototypes, fabrication of biomedical structures like hearing aids, prosthetics for amputees and disabled, toys and decorative products, demonstrative models for educational institutions etc. to name a few.

The lab is subdivided into 4 sections to facilitate the projects done in Design, 3D Lab, Laser machines lab and Prototyping lab.

The lab is subdivided into 4 sections to facilitate the projects done in Design, 3D Lab, Laser machines lab and Prototyping lab.

- Design Lab: It comprises of workstations equipped with licensed software necessary for 3D designing for printing.

- 3 D lab: It comprises of multiple number of 3D printers that can handle different materials like PLA, ABS, Nylon and Flexible filaments as per the product demand, Dual head printer for printing features with improved aesthetics and properties and a Human body size 3D printer for carrying out research in prosthetic development.

- Prototyping Lab: It comprises of equipments like Micro-Lathe, Table Top Drilling Machine, Cutter Table Top, Grinder (Surface Grinder Miniature Type), Sand Blaster, Welding Machine Electronic Type etc. which will facilitate in the final round processing of the developed product or prototype.

Currently, the Central Government is promoting the schemes related to MAKE IN INDIA and facilities like this will be a stepping stone to such noble initiatives. Similarly, the Government of Kerala has constituted two Fab Labs at different places under Kerala Start Up Mission, which has motivated many to learn and acquire such skills. On a similar note, the Additive Manufacturing Zone in Amal Jyothi will serve as a hub for research in additive manufacturing, platforms for young entrepreneurs and facility for student as well as teaching fraternity to carry out their academic as well as research projects. Further, collaborations with reputed firms in the field will increase the output of the facility in academic as well as societal responsibility fronts.

Currently, the Central Government is promoting the schemes related to MAKE IN INDIA and facilities like this will be a stepping stone to such noble initiatives. Similarly, the Government of Kerala has constituted two Fab Labs at different places under Kerala Start Up Mission, which has motivated many to learn and acquire such skills. On a similar note, the Additive Manufacturing Zone in Amal Jyothi will serve as a hub for research in additive manufacturing, platforms for young entrepreneurs and facility for student as well as teaching fraternity to carry out their academic as well as research projects. Further, collaborations with reputed firms in the field will increase the output of the facility in academic as well as societal responsibility fronts.

An overview of Fab Lab at Amal Jyothi (Additive Manufacturing)

Inaugurated on : 14 Nov 2019 by the Hon'ble VC of APJ AKTU

Area of the facility : About 4400 Sq ft, including Corridors

Investment on machinery and furniture : Rs 20 Lakh

Source of investment : In-house by Amal Jyothi College of Engineering

Major equipment installed:

- 3-D Printers

- Work Stations

- Micro lathe

- Table top Drilling Machine, Cutter and Surface Grinder

- Welding Machine

- All Basic Tools

- Students can work on their own idea and build a prototype using the concept of 3D printing.

- Providing a workspace for carrying out various advanced machinery for the fabrication works regarding projects and start-ups.

- Opportunity for students to master the various pieces of digitally controlled hardware.

- Infrastructure for research projects, Technology Development and Product Realization.

- Institute Industrial Interaction: Leading to join projects and research activities

- In-house training for students and quality improvement programs for faculty

- Facilitate a platform for externally funded research

- Facilities for research scholars for the research work

- Faculty Development Programmes for teachers

- Conduction of exclusive workshops and awareness programmes on various verticals related to the Additive Manufacturing, Product Design and Development and Entrepreneurship.

- Provision for training and certification of all staff, volunteers, interns, and guests on the use of the state of the art product development and validation technologies.

9. Cryogenic Treatment Laboratory

Cryo Lab is established as a joint venture of ISRO and Amal Jyothi college for completing the low-temperature treatment studies of materials provided by ISRO. This is one of the research labs which focuses on studies happening in the materials science field and is open to all. The lab facility has the potential to cool down the materials to extremely low temperatures. Many undergraduate and postgraduate projects have been completed and researchers within and outside the college use the facilities.

Cryo Lab is established as a joint venture of ISRO and Amal Jyothi college for completing the low-temperature treatment studies of materials provided by ISRO. This is one of the research labs which focuses on studies happening in the materials science field and is open to all. The lab facility has the potential to cool down the materials to extremely low temperatures. Many undergraduate and postgraduate projects have been completed and researchers within and outside the college use the facilities.

- Sub-zero treatment unit (can go up to -80 °C)

- Cryo Chamber (can go up to -196 °C )

- Liquid Nitrogen transferring device

- Liquid Nitrogen Containers